THE STATUS OF STEAM LOCOMOTIVE

COOS BAY LUMBER CO #11

Click on any photo for larger version

In 2008, we contracted with a very experienced and respected locomotive boiler inspector, Dave Griner, of Arizona Mechanical Engineering, to examine the boilers on both Southern Pacific 2353 and Coos Bay 11.

|

|

|

In order to get a good look at both the exterior and interior surfaces of the boiler, it would be necessary to remove the outer jacket and asbestos insulation, and all the boiler tubes. Then, all the accumulated scale and other crud that has collected inside the boiler would have to be cleaned out.

Fortunately, a number of years ago, a generous donor had agreed to do asbestos

abatement work on all five of the steam locomotives we have at Campo. As part of that

process, the saddle tank and sheet metal jacket had also been removed, so the

locomotive was ready for us to start doing our job.

|

During the past several years, our volunteers have worked on this project, putting in

over 1,100 man-hours (including some woman-hours). Sometimes the progress was

very slow, since a number of jobs required extensive "learning time."

In approximate order, we accomplished the following:

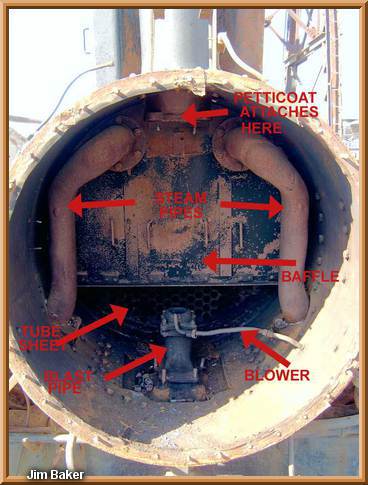

| Removed the: | | smoke box door | smoke box front Photo 1

| petticoat pipe | blast pipe smoke box baffle Photo 2

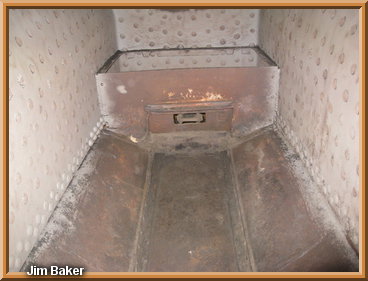

| fire brick from the fire box | Photo 3

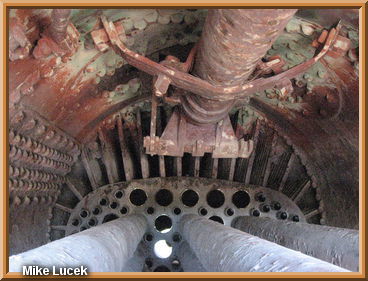

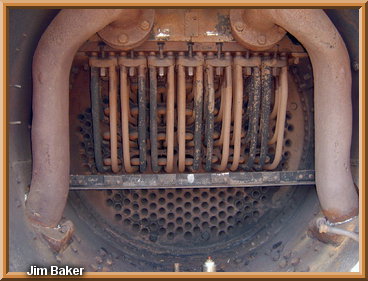

| all 26 superheater units | throttle spool Photos 4 & 5

| 23 of the 26 superheater flues | Photos 6 & 7

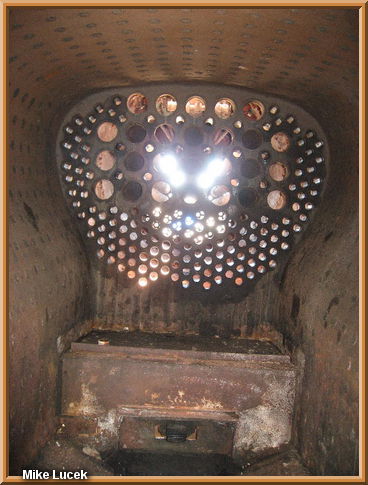

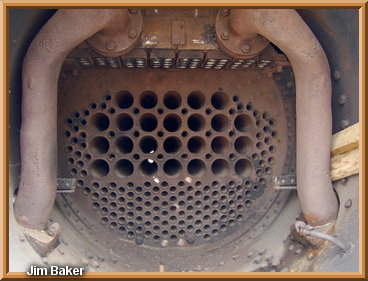

| 160 boiler tubes | (short stubs remain at both tube sheets) Photo 8

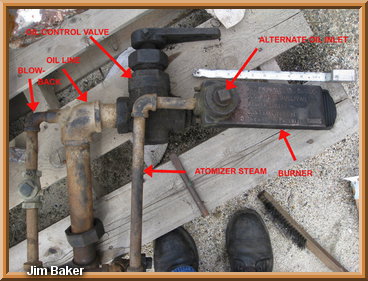

| oil burner | Photo 9

| throttle | 14 of 23 wash-out plugs Photo 10

| And we: | wire-brushed and vacuumed out all tubes prior to removal |

| pressure washed the boiler interior |

| cleaned out the sand domes (2) |

| lubricated the running gear so the locomotive could be moved |

| inspected the valve cylinders | Photo 11

| boxed and stored the cross-compound air compressor |

| made covers for the dry pipe and superheater header |

| had the boiler interior sand-blasted by a contractor | Photos 12-16

| vacuumed and washed remaining sand from around the mud ring |

| Bob, Jim, Mike and Rich pose on #11 | Banner Photo

| Now (Aug., 2010) our next few jobs:

| lubricate the running gear again

| lubricate the running gear again

| remove the tube stubs from the front tube sheet

| remove the remaining wash-out plugs

| draw a 1ft. X 1 ft. grid on the boiler for ultrasound measurements

| Status for year end 2010:

| Running gear has been thoroughly lubricated

| All wash-out plugs have been removed, lubricated, and re-installed to keep out the rain

| A plywood cover for the front of the smoke box was fabricated and installed

| Thirty of the 160 tube stubs have been removed from the front tube sheet

| Most of a 1 ft. X 1 ft. grid has been drawn on the boiler

| For the first part of 2011 we plan to:

| Finish removing the tube stubs from the front tube sheet

| Finish drawing the ultrasound grid

| Do the ultrasound testing

| | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||